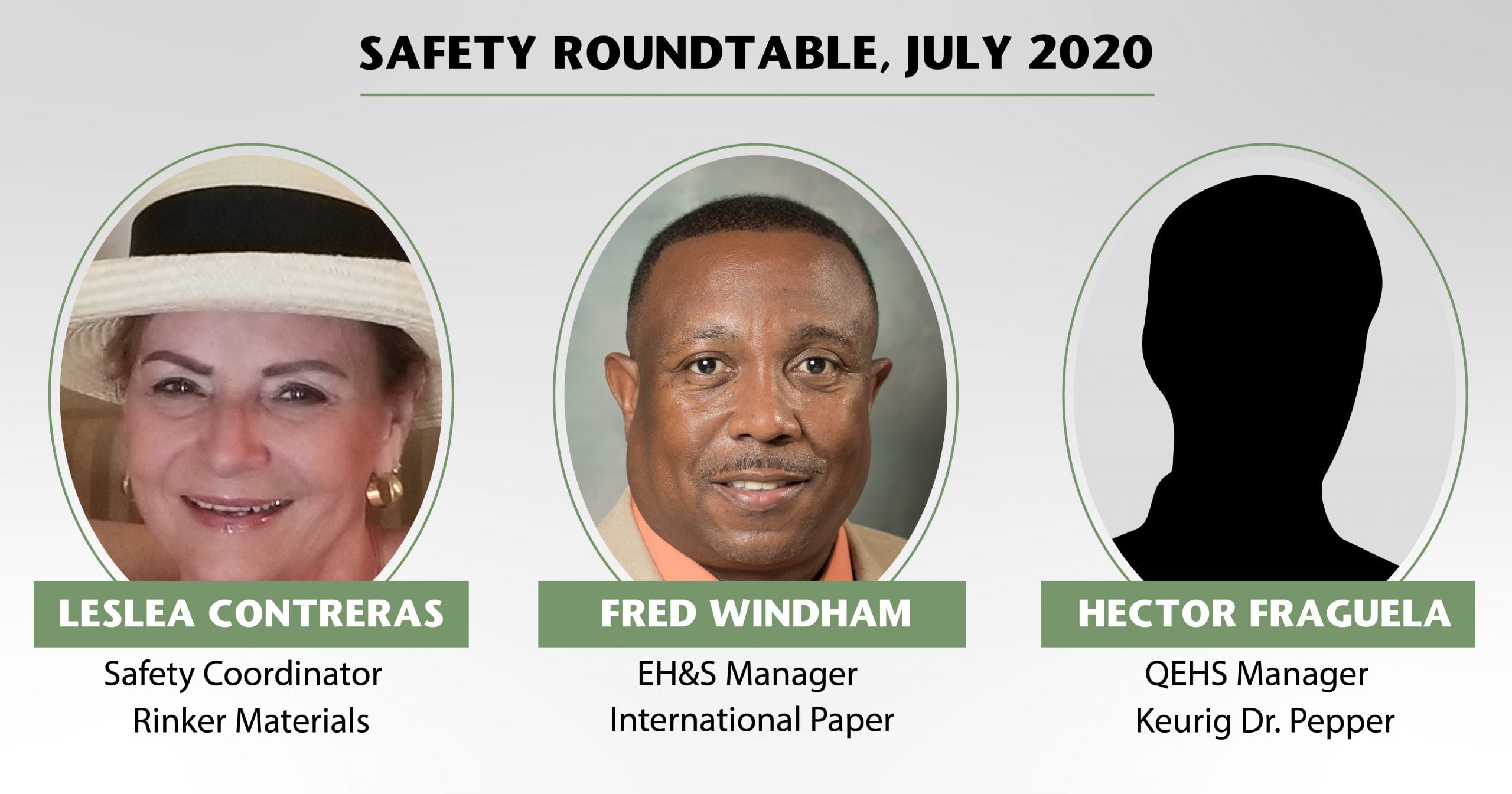

Ever wish you could learn from some experienced safety managers at leading companies? Check out our most recent roundtable with three such safety experts. You will learn how to solve the most recent safety challenges and learn some tips to advance your career.

Q - What do you think will be the most important safety issues this year? What initiative(s) does your company/facility/department have this year for EHS?

FW - Unexpectedly, one of the biggest initiatives and focuses this year centers around COVID-19. The pandemic forced the facility to switch gears during the first quarter of the year to help ensure all team members were educated, equipped and prepared, as much as possible, relative to COVID-19. Adding layers of protection to the facility’s existing Health and Safety program has been instrumental in reducing COVID-19 exposures. Those measures include temperature screening prior to entering the mill, required completion of Close Contact Forms daily by all team members, requiring face coverings in situations where social distancing is not possible and enhanced daily cleaning for all areas of the facility.

LC - My current challenge, and I’m sure it will continue throughout the year, is safety supply and cleaning supply. It has been extremely difficult to purchase simple items like face shields and dust masks to protect employees during their daily work activities. We have resorted to purchasing shields online, however they are not up to the safety level needed for the work we do. Cleaning supplies that contain disinfectant are also hard to find. If they are at a local store, there is a limit to how much you can buy and I have to go back several times to purchase enough to clean the shop. This also lowers the availability for household shoppers. We need to find a balance between frontline workers, business buyers and the general public to avoid all of us ending up at the hospital eventually due to exposure from lack of safety & cleaning supplies.

HF - I’m pretty sure that COVID-19 blew up everybody’s plans. Whatever was your top priority entering the year probably got bumped down on the list. Our biggest initiatives focus on COVID-19 right now and that will probably be the case for all of us for a while.

Q - What have you learned from your hearing conservation and/or respiratory protection compliance programs?

LC - By testing and monitoring annually, I am assured the hearing protection we are using is effective in protecting our employees’ hearing. If there is a shift in an employee’s hearing, I investigate to see if there’s an at-home activity that is causing the damage or has there been a change in the work he is performing that needs additional hearing protection. These determinations allow us to protect our workers better.

FW - We do IHS every 5 years. Along with being an OSHA requirement, it helps us gauge what our workers are exposed to and if the processes we have in place are working to protect our employees. What we have learned with these studies is how well we are protecting them. If there is an issue of overexposure, either to noise or respiratory hazards, we put processes in place immediately to correct it, and if needed retraining is implemented.

HF - By living these programs day in and day out, I’ve learned there are always ways to keep improving. Whether it’s using better PPE or upgrading our systems capabilities for noise reduction or something else, it’s an ongoing process that is never finished.

Q - What advice do you have for a new safety pro just entering the EHS field?

FW - First, “walk the talk” and lead by example. Also, make sure you build strong and meaningful relationships throughout the organization. Listen to team members instead of just hearing team. Lastly, always have the courage to intervene, no matter how long you have been in your role.

LC - Fred nailed it. It’s important to build a sense of teamwork within your site by everyone working together and developing tight relationships. Another tip for newbies is to think of your vendors as partners and have them demonstrate their products and show the safety features. Not only will they be excited to do this, but it gives you a resource to gain some expertise in different areas.

HF - Similar to what’s been said, relationships are key. That’s what opens the door for communication. When things breakdown or go wrong or an issue arises, you’ll have the foundation to have the honest discussions you need.

Q - What tips or tricks do you have for increasing employee engagement with health & safety?

LC - You need to get the engagement of all employees, it’s not just one person’s responsibility. Participation should not be an option. Actually, if someone doesn’t want to participate, that is a huge red flag. In some cases, they may need to find employment elsewhere. When everyone is onboard, safety is being embraced completely as it should be.

HF - I totally agree with Leslea. We have created a safety culture by involving all the employees at the site. Not just certain workers or those with specific exposures. But most important, we talk about safety every day. It’s not a sometimes thing, it’s an everyday thing. That helps keep it top of mind.

FW - It important to note that unlike most broader corporate safety and health programs, a facility’s safety culture is created over time. There’s several factors that influence a facility’s safety culture, such as people, leadership, health & safety programs, clear expectations and team members having the courage to intervene when necessary.

A facility’s safety culture is forever evolving, therefore so should your safety programs. As my colleagues here have mentioned, one of a facility’s biggest resources in keeping programs fresh and shiny is involvement from our team members. Developing and/or revising programs with the impute of team members provides a sense of ownership and buy-in from employees. The more opportunities team members have to participate in programs and share their opinions, the more that directly influences culture.

Q - What are your favorite resources to stay on top of safety trends? How do you continue to grow as a safety pro?

FW - Once again, I would say employee involvement/engagement is the greatest resource at the facility. We feel growth comes with continuously educating, training and providing a platform for employees to be involved in our safety and health programs. Our team members serve on various safety committees that analyze safety trends within the facility. Through employee involvement, we drive and analyze safety trends in various areas. These include Safety Work Observation and Engagement, which we consider a leading indicator; Hazard Recognition and Mitigation, which also is a leading indicator; and LIFE Potential Analysis, meaning completed investigations within a certain timeframe for injury/near misses that can have a LIFE changing impact on a person.

HF - I recommend attending OSHA training when available. Not only do we stay on top of the latest rules and maintain our compliance standards, but it helps me become an effective trainer to our workers. I can develop and deliver quality training that educates and empowers our team.

LC - I like to invite local authorities to bring in their knowledge, such as the Fire Department. They are always willing to share their expertise and teach our employees safety tips and proper equipment use. Also, we have been talking about engagement with employees – we let our employees know the date so they can bring their spouses and children. The Fire Department will bring hats and stickers for the kids and they will allow them to use a fire extinguisher and put a fire out. This will help if a fire breaks out at home; they will understand what to do. They also bring the fire truck and allow the kids to sit in the driver’s seat and blow the horn. Plus, the kids love being able to visit mom or dad at work.

---

This is business-to-business information intended for EHS (environmental health and safety) professionals and not intended for the final consumer. Companies should check the local regulatory status of any claim according to their individual needs, requirements and intended use.